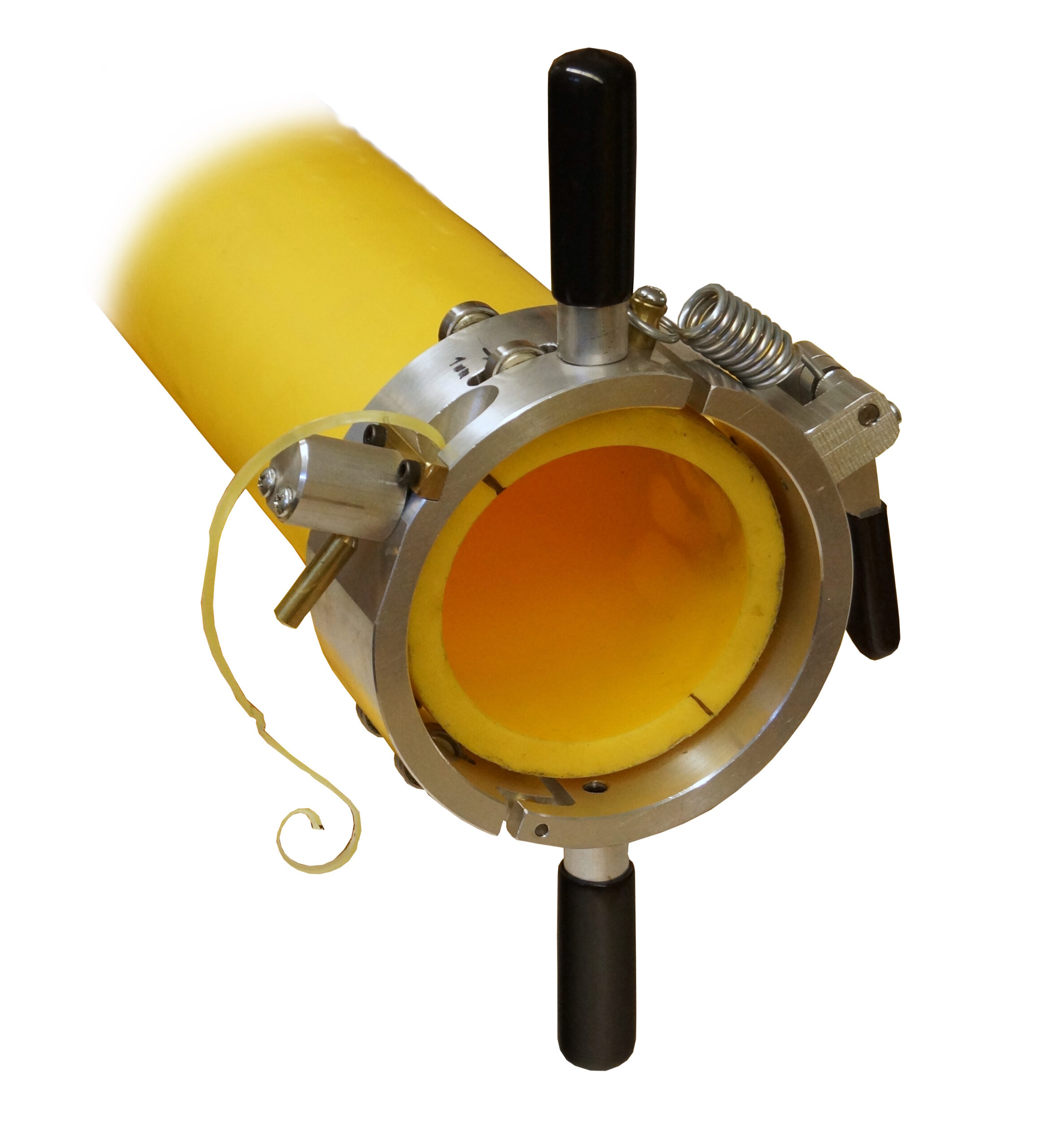

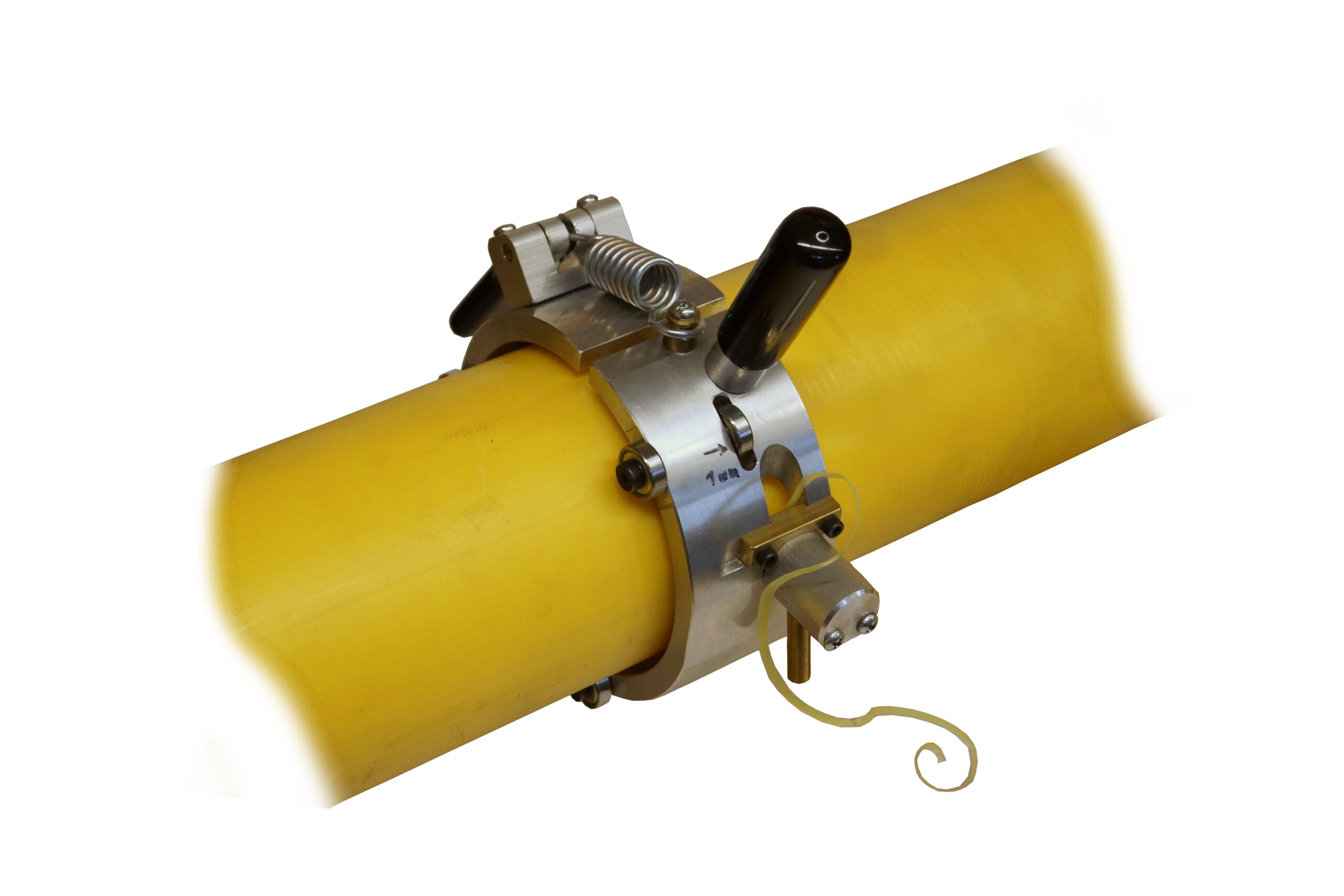

The Split Peeler is the original rotary pipe scraper for removal of contamination from the pipe outside diameter to prepare for electrofusion installation of couplings, tapping tees and other fittings.

Meets the guidelines of the Plastics Pipe Institute‘s Electrofusion Procedure for Field Joining PE Pipe. If you look closely you will even see images of our peelers in the procedure!

Building on 20+ years of service in industry, the Split Peeler now includes several new features to maximize performance and ease of use.

Features:

- Removes a continuous peel of material from the pipe OD

- For use on straight or coiled pipe, on continuous pipe (saddles, tapping tee installation) or at pipe ends (coupling installation)

- Sizes from 1-1/4″ to 12″ IPS (for smaller applications see our Pipe Surface Peeler)

- No internal mandrel means no access required to ID of pipe

- Latch-type closure for fast installation on pipe

- Spring loaded cutting tool follows contour of pipe even with oval/out-of-round conditions (within pipe manufacturers’ limits)

- No tool contact with the pipe surface after peeling to prevent re-contamination

- Aluminum construction for reduced weight and corrosion resistance

- Field-replaceable cutting tool and rolling elements

- Many common spare parts between all sizes of Split Peeler

- Patented design